JIANGSU WELLHEAD DRILLING EUIPMENT CO., LTD. was founded in February 2005 and is a national high-tech manufacturing enterprise that integrates R&D, production, sales, and service, specializing in intelligent equipment for oil and gas drilling and production. The company is dedicated to the design, development, and manufacturing of a series of products including wellhead equipment, casing heads, blowout preventers, choke and kill manifolds, mud pumps and drilling mud manifolds, as well as high-and-medium-pressure valves and drilling accessories for oil and gas extraction. JIANGSU WELLHEAD DRILLING EQUIPMENT CO., LTD. is a designated one of suppliers for CNPC, SINOPEC, and CNOOC's for material and equipment.

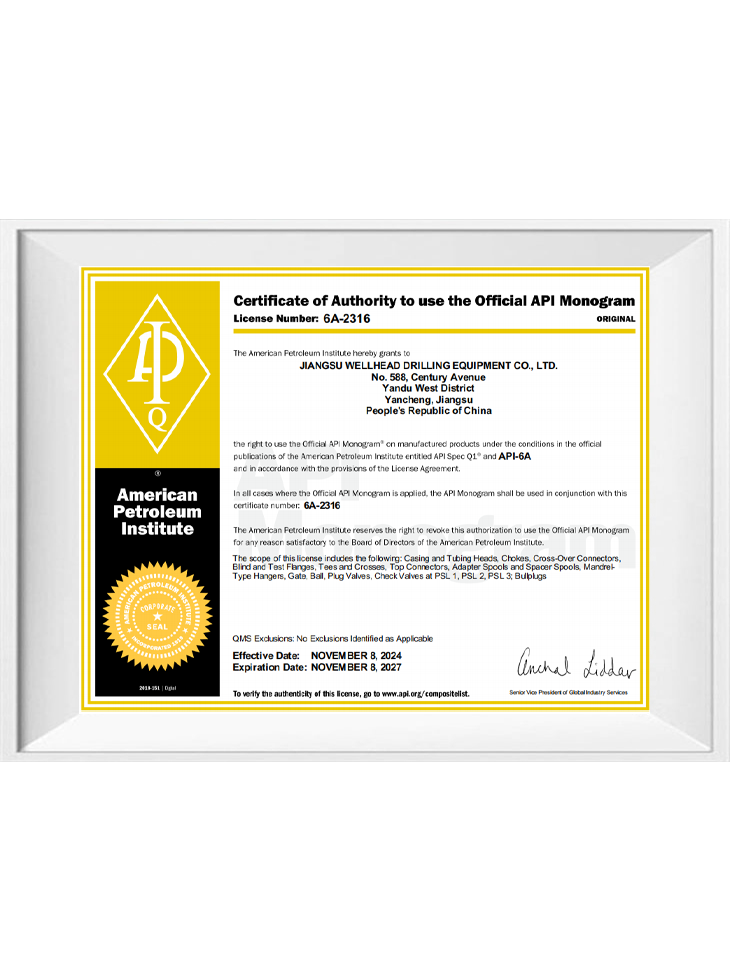

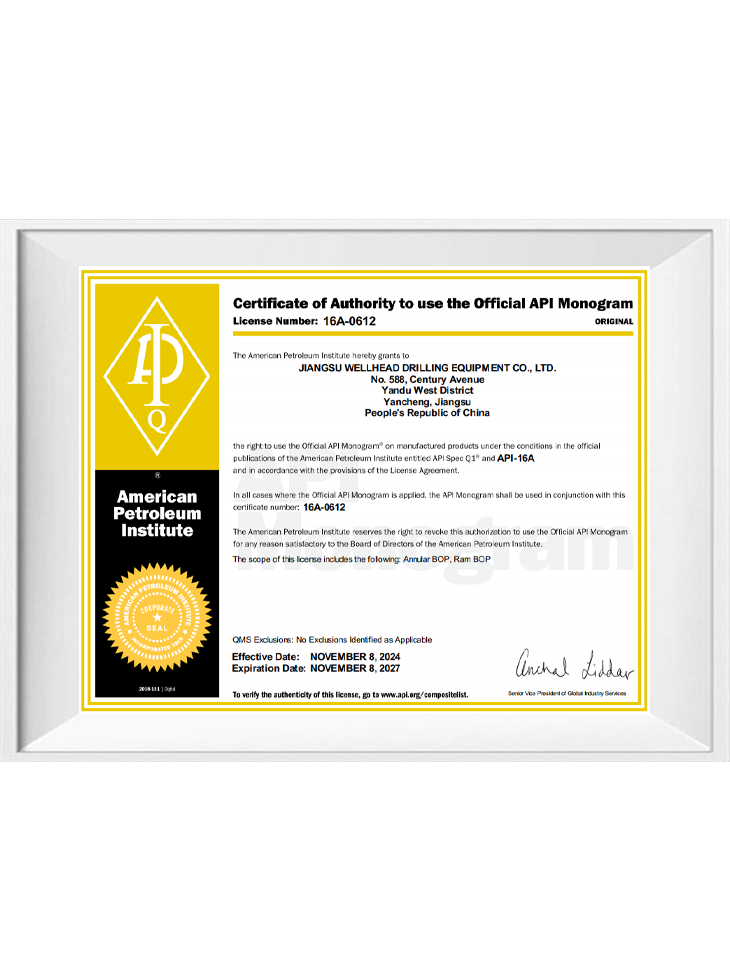

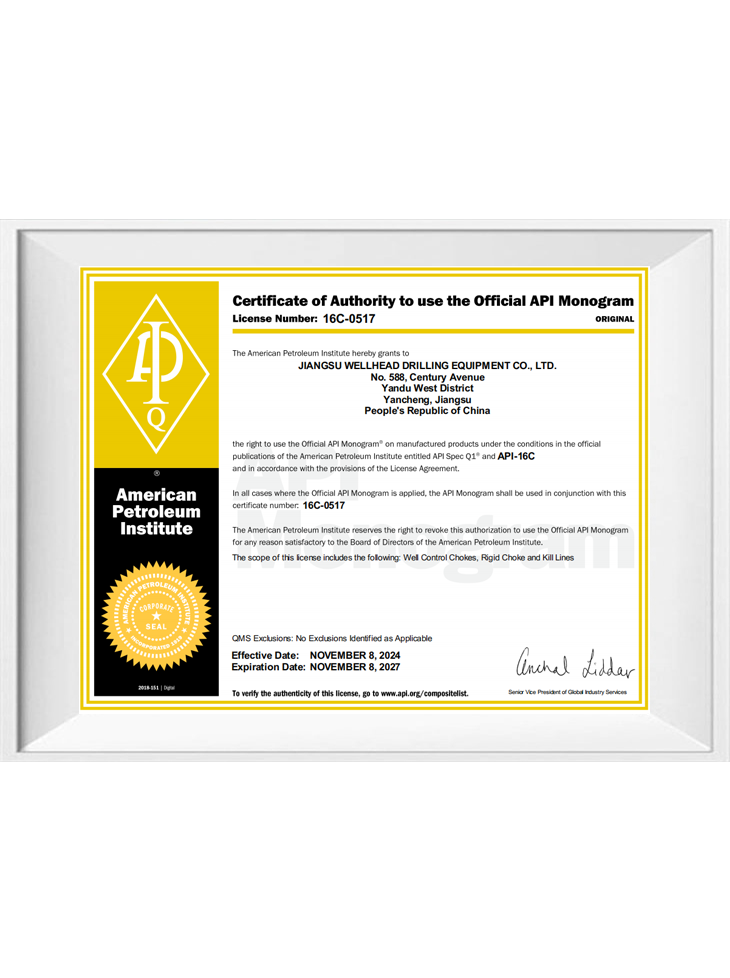

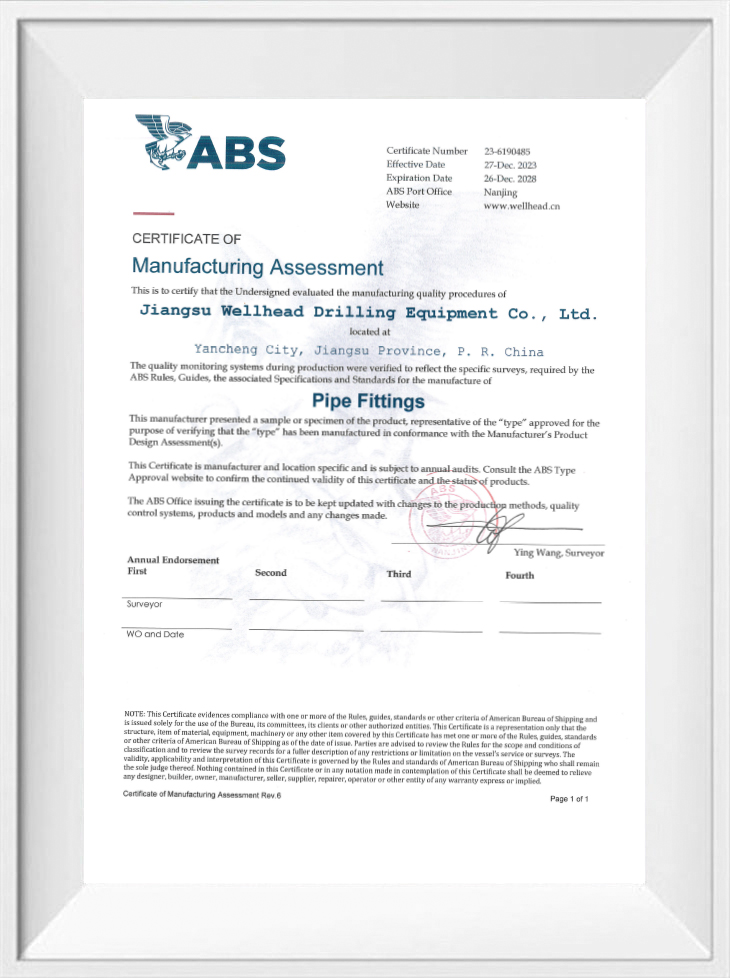

JIANGSU WELLHEAD DRILLING EUIPMENT CO., LTD. was the first enterprises to settle in Yancheng National High-Tech Industrial Development Zone, covering land of an area of about 70000 m². We have constructed four modern standardized workshops of which total construction area is 50,000 m². Our factory are equipped with world-class advanced CNC machining, automated welding machine, and auto-spray-painting equipment. We currently have more than 100 employees, including over 20 middle and senior technical professionals and over 40 skilled middle and senior technicians. We have API certifications including: API Q1, API 6A, API 16A, and API 16C and monogram licenses. Also our company are certificated by ABS (American Bureau of Shipping), BV (Bureau Veritas), and CCS (China Classification Society).

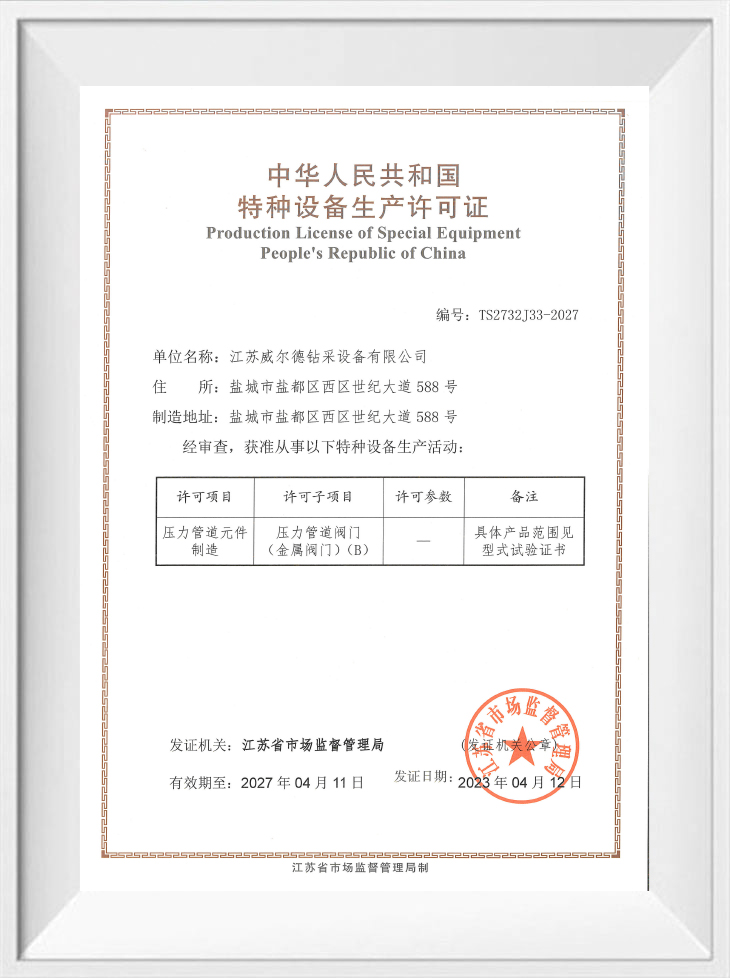

A pioneer in its industry, Jiangsu Wellhead has achieved certifications for ISO 9001 Quality Management System, ISO 14001 Environmental Management System, and ISO 45001 Occupational Health and Safety Management System. Additionally, the company has been certified in multiple management systems, including AAA Measurement System, Green Packaging, Green Supply Chain, Green Design Product Management, Energy Management, After-Sales Service, Intellectual Property, and Carbon Footprint Management.

As a professional

API 6A Safety Valve Manufacturer and

Wholesale Safety Valve Factory

+ 86-0515-88429333

+ 86-0515-88429333